Introduction:

The era of fossil fuel dominance is facing an unprecedented challenge. Amidst growing concerns over climate change and an intensifying race towards a sustainable future, a new contender has emerged in the global energy landscape—green hydrogen.

Produced through water electrolysis using renewable energy sources like solar and wind, green hydrogen holds the promise of a zero-carbon fuel with potentially transformational applications across industries.

Green hydrogen has become a global cornerstone of energy transition strategies as nations scramble to decarbonize by 2050 and reduce their reliance on volatile fossil fuel markets. With the potential to revolutionize industries ranging from transportation to heavy manufacturing, the stakes are high in the competition to develop and establish large-scale green hydrogen economies.

This fight for global energy dominance isn’t simply about cleaner energy sources but geopolitical realignment. Countries positioned to establish leadership in green hydrogen production and technology stand to gain significant economic, environmental, and strategic advantages.

This dynamic sets the stage for a fierce new energy race that will reshape industries, international relationships, and the very future of our planet.

What is Green Hydrogen?

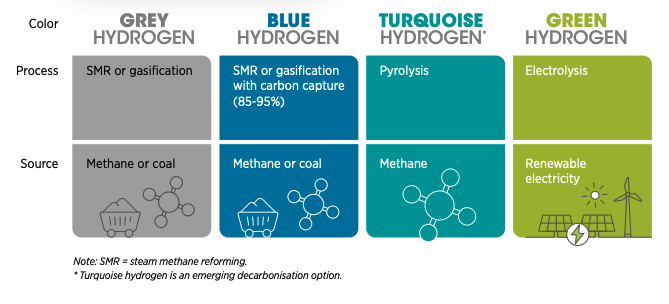

Green hydrogen is a zero-carbon fuel produced through a process called electrolysis, where water (H₂O) is split into hydrogen (H₂) and oxygen (O₂) using electricity derived from renewable energy sources like solar, wind, or hydropower.

Hydrogen causes 2% of current global CO₂ emissions. This renewable-powered approach distinguishes green hydrogen from other types of hydrogen production that may use fossil fuels.

Here’s the key takeaway: It offers the possibility of storing and utilizing clean energy without greenhouse gas emissions, making it a vital element in the quest for a decarbonized energy future.

How is Green Hydrogen Produced?

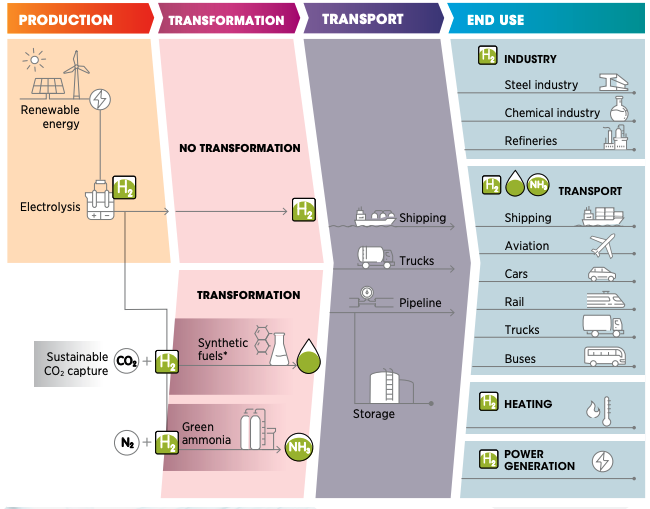

Renewable Energy Source: Green hydrogen production begins with electricity generated from renewable sources like solar, wind, or hydropower. This clean energy is essential for ensuring the sustainability of the hydrogen produced.

Electrolyzer: The heart of the process is the electrolyzer, a device designed to split water molecules. It contains two electrodes (an anode and a cathode) submerged in an electrolyte solution.

Optimizing the synergy between renewable energy sources and electrolyzer operations is crucial for maximizing efficiency and minimizing costs.

Electrolysis: Water molecules are broken down when electricity flows through the electrolyzer. At the anode, oxygen gas (O₂) is released. At the cathode, hydrogen ions (H+) gain electrons and become hydrogen gas (H₂).

Hydrogen Collection and Storage: The pure hydrogen gas is collected and can be stored for later use as fuel in various applications.

Types of electrolyzers:

Alkaline Electrolyzers: The most mature and established technology. They use a liquid alkaline solution as the electrolyte. Alkaline electrolyzers are cost-effective, but they operate at lower efficiencies and have slower response times to changes in energy input.

Proton Exchange Membrane (PEM) Electrolyzers: Use a solid polymer membrane as the electrolyte. PEM electrolyzers are well-suited for applications requiring rapid response to fluctuations in renewable energy input. They are more compact but generally more expensive than alkaline electrolyzers.

Solid Oxide Electrolyzers (SOE): SOEs operate at very high temperatures (600-1000°C) using a solid ceramic electrolyte. They offer the highest potential efficiencies but come with drawbacks of slower startup times and complex materials requirements. SOEs are still in the earlier stages of development but hold promise for the future.

Key Renewable Energy Sources Used to Power Electrolysis for Green Hydrogen Production:

Solar Power:

Solar photovoltaic (PV) systems convert sunlight directly into electricity. The flexibility of solar installations, from rooftop panels to large solar farms, makes them highly adaptable for green hydrogen production. Advancements in solar technology continue to drive down costs while increasing efficiency.

Wind Power:

Onshore and offshore wind turbines harness the kinetic energy of wind to generate electricity. Wind power is a mature technology with increasingly large-scale installations providing substantial capacity for electrolysis. However, the intermittent nature of wind can lead to fluctuations in power output, requiring strategies for energy storage and balancing.

Hydropower:

Hydroelectric dams use the potential energy of water to drive turbines and generate electricity. As a highly reliable and controllable energy source, hydropower offers advantages for stable electrolysis operations. Nevertheless, concerns exist about the environmental impact of large hydropower projects.

Other Renewables:

While less common, other renewable resources can contribute to green hydrogen production. These include:

Geothermal Energy: Heat from the Earth’s interior produces steam, which drives electricity generation.

Biomass Energy: Burning sustainably sourced biomass (plant or animal material) can create heat to produce steam for electricity generation. Its role in this hydrogen depends on sustainable sourcing to avoid contributing to deforestation and land-use issues.

Advantages of Green Hydrogen:

Zero-carbon emissions: During use, only emitting water vapour. Green Hydrogen generation will prevent annual 830 million tonnes of CO2 emissions using fossil fuels.

Energy storage: Excess renewable energy can be converted into hydrogen, addressing intermittency issues.

Versatility:

- Replace fossil fuels in heavy industry (steel, cement): Substituting green hydrogen in steel production could reduce emissions by millions of tons of CO2 annually.

- Long-distance transportation fuel (trucks, ships): Green hydrogen’s energy density offers advantages for long-haul trucking and shipping compared to battery-electric options.

- “Green” fertilizer production (ammonia)

Challenges Facing Widespread Adoption of Green Hydrogen:

Despite its immense potential, green hydrogen faces several obstacles to becoming a mainstream energy source. These challenges must be addressed to drive down costs, increase efficiency, and create the necessary infrastructure for a thriving green hydrogen economy.

A. Electrolyzers and Renewable Infrastructure Remain Expensive

Electrolyzers: Electrolyzers, particularly newer technologies like PEM, are still costly to manufacture and install on a large scale. Materials and design research and development are crucial for lowering production costs.

Renewable Energy: While renewable energy costs have dropped dramatically, building the massive solar and wind farms required for substantial green hydrogen production remains a significant investment.

B. Energy Losses Occur During Conversion and Storage

Electrolysis: The electrolysis process is inherently energy-intensive, and some energy is lost as heat. Improvements in electrolyzer technology aim to increase efficiency to maximize the hydrogen output per unit of electricity input.

Storage and Conversion: Compressing, liquifying, or transporting hydrogen requires additional energy. Moreover, hydrogen can leak from storage systems. Efficiency gains in both storage methods and the reconversion of hydrogen into electricity (e.g., fuel cells) are essential.

C. Hydrogen Transport and Distribution Networks Need Significant Infrastructural Development

Pipelines: Building dedicated hydrogen pipelines or retrofitting existing natural gas pipelines poses logistical and financial challenges.

Transportation: Transporting hydrogen by truck, especially in liquefied form, can be energy-intensive and costly for long distances.

Refueling Stations: A comprehensive network of hydrogen refueling stations is necessary for applications like fuel cell vehicles. This needs extensive investment and planning.

These challenges highlight the need for technological innovation, policy support, and strategic investment to create a favorable environment for the green hydrogen industry to flourish.

Current Global Scenario of Green Hydrogen:

A. Major Green Hydrogen Projects and Investments Worldwide

NEOM (Saudi Arabia): This mega project aims to produce 650 tons of green hydrogen daily using 4 GW of solar and wind energy. The hydrogen will be converted to green ammonia for export.

Asian Renewable Energy Hub (Australia): A massive project planned to utilize 26 GW of wind and solar energy, producing up to 1.6 million tons of green hydrogen annually.

Helios Green Fuels Project (Egypt): A project focused on generating green hydrogen via electrolysis and its conversion to green ammonia for fertilizer production and export.

Numerous European projects: Countries like Germany, the Netherlands, and Spain are investing heavily in green hydrogen initiatives, with numerous projects in various stages of development.

B. Leading Countries in Green Hydrogen Technology and Policy-making

European Union: The EU has ambitious green hydrogen targets and strong policy support through its Hydrogen Strategy. Individual countries like Germany are spearheading major investments.

Australia: With abundant renewable resources and export ambitions, Australia’s National Hydrogen Strategy aims to position the country as a global player.

Japan and South Korea: Both countries consider green hydrogen vital to their decarbonization goals. They are investing in research, domestic production, and international partnerships.

China: China is rapidly emerging as a major player in both hydrogen production and electrolyzer manufacturing capacity.

Other Emerging Leaders: Countries like Chile, Morocco, Oman, and India recognize green hydrogen’s potential and are developing strategies and projects.

C. Collaboration Between the Private Sector and Governments to Drive Innovation

Collaboration between industry and governments is crucial for overcoming challenges and accelerating green hydrogen development. Here’s why:

Funding: Governments provide subsidies, tax credits, and research grants that support and de-risk investments in green hydrogen technology and projects.

Regulation: Policy frameworks set targets, create favorable market conditions and provide a predictable environment for business investment.

Partnerships: Public-private partnerships can share costs, risks, and expertise in driving large-scale infrastructure projects and technology development.

International Cooperation: Cross-border collaborations promote knowledge sharing, technology transfer, and the establishment of global hydrogen supply chains.

The Future of Green Hydrogen:

A. Projections and Forecasts for the Growth of the Green Hydrogen Market

Rapid Expansion: Analysts anticipate a dramatic growth trajectory for green hydrogen. Research organizations like BloombergNEF and the International Energy Agency (IEA) project that the global hydrogen market could reach hundreds of billions of dollars by 2050 and that the share of green hydrogen will significantly increase.

Demand Drivers: Growing climate commitments, decarbonization mandates, and falling renewable energy costs drive the demand for green hydrogen. Industry sectors eager to lower emissions (steel, chemicals, long-distance transport) present a huge market opportunity.

B. Expected Decreasing Costs as Technology Matures and Scales Up

Electrolyzers: Mass manufacturing, innovation in materials, and design improvements will likely reduce electrolyzer costs significantly. Some projections suggest reductions upwards of 80% by 2050.

Renewable Energy: Continued cost declines in solar and wind power make the electricity powering electrolysis cheaper, directly impacting green hydrogen production costs.

Economies of Scale: Larger-scale projects, standardized components, and efficient supply chains offer further potential for cost reductions.

C. The Essential Role of Green Hydrogen in Achieving Net-Zero Emissions Targets

Tackling “Hard-to-Abate” Sectors: Green hydrogen holds the key to decarbonizing sectors where direct electrification is challenging or impossible, such as Heavy Industry. Green hydrogen can replace fossil fuels in steelmaking, ammonia production for fertilizer, and chemical processes.

Long-Distance Transportation: Hydrogen fuel cells offer an alternative to batteries for ships, trucks, and potentially aviation.

Energy Storage: Green hydrogen can store excess renewable energy, addressing intermittency and helping balance the grid.

Net-Zero Enabler: The International Renewable Energy Agency (IRENA) emphasizes that green hydrogen is critical to achieving net-zero emissions and limiting global warming. It will play a supporting role alongside direct electrification and energy efficiency measures.

Complementary Technologies: Green hydrogen will function most effectively when integrated into a broader energy system alongside decarbonization technologies like carbon capture and storage (CCS), nuclear power (where applicable), and advanced batteries.

Green hydrogen is not a silver bullet; challenges related to efficiency and infrastructure necessitate continuous investment and a clear-eyed approach.

Conclusion:

As the world races toward a carbon-neutral future, green hydrogen emerges as a transformative energy carrier. Its ability to be produced from renewable resources, its versatility in applications across various sectors, and its potential to decarbonize traditionally polluting industries, solidify green hydrogen’s role as a cornerstone of the energy transition.

However, to fully unlock the potential of green hydrogen, we must actively address the challenges of cost and infrastructure. A strong call to action is needed. The stakes are high, and the rewards—a cleaner, more sustainable planet and new economic opportunities—make this investment compelling.

Let’s work collectively to create the conditions where green hydrogen can propel us forward, leaving a legacy of innovation and environmental stewardship for generations to come.